Paint and coating thickness evaluation

Large area thickness measurements on coated surfaces

Large area thickness measurements on coated surfaces

Paints and coatings are ubiquitous in modern life and applications are found in nearly every industry segment. The requirements on modern paints and coatings are high - they need to be abrasion and corrosion resistant, weather permanent, environmentally friendly and at the same time have the right visual appearance. To ensure these properties on coated end products, good control over parameters like surface roughness, homogeneity and thickness is crucial. With hyperspectral imaging all those parameters can be measured and monitored both during application and curing of the coating as well as after for inspection and control. While conventional technologies are restricted to pointwise measurements, hyperspectral imaging allows for scanning larger areas giving a more complete picture of the coating properties.

In this study we investigate a set of 8 painted panels with different dry film thicknesses (DFT) The goal is to use supervised machine learning algorithms on the spectroscopic information of the painted panels to predict thickness on new samples. The coated panels are shown in Figure 1, color coded and labeled with a reference DFT value. These values were measured in one location only and does not take intra-sample thickness variation and inhomogeneity into account.

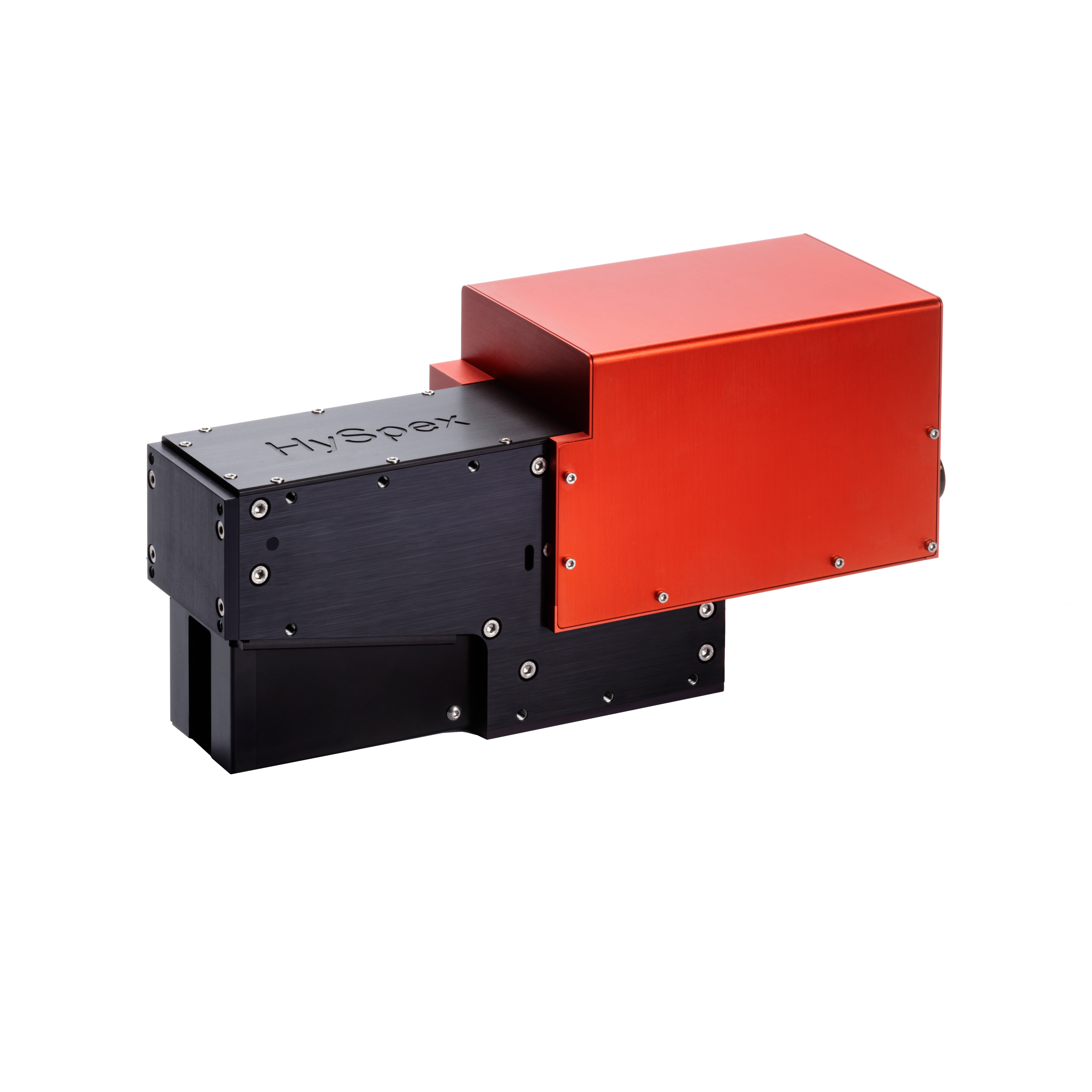

Starting the hyperspectral measurement, light reflecting off the surface of the panels is captured by the HySpex SWIR-384 hyperspectral camera, recording the complete spectral information in the wavelength region of 930-2500nm for every single pixel within the scene. To train the model we are only interested in the mean spectral properties of each panel, which are shown in Figure 2. While we can hardly see any differences between the panels with the blank eye, the spectral response detected by the camera clearly shows a shift in reflected intensity along large parts of the spectrum.

This distinctive information can be used to train a PLS regression model. Once a model is made it can then be used to predict DFT values of each pixel in new images allowing us to either calculate an average sample value or to inspect thickness variation within each sample.

The dataset is relatively small for creating a regression model so Leave-One-Out Cross Validation (LOOCV) is applied to avoid overfitting the data. With LOOCV we train the model with 7 out of the 8 samples, test it on the left-out sample and repeat the procedure for all permutations. Predicted vs. reference value is plotted in Figure 3. The R2 regression score when including all samples in the model is above 0.99 while for the cross validated model the regression score is 0.86. This indicates a very good model fit, especially considering the small dataset and the point measured reference values.

This analysis shows that hyperspectral imaging with HySpex camera systems has great potential to be an effective and accurate tool for paint and coating thickness evaluation. For the detection capabilities do not stop here. High spatial resolution and spectral fidelity allow for analysis of much finer details like local thickness variation, pinholes or other defects on pixel and even subpixel level. HySpex offers a varied selection of turn-key solutions for scientific and industrial applications.

Download this application note.

Pharmaceuticals

Methane Detection

Plastic Sorting

Mineral mapping in open pit mines

Asbestos

Explosives

Hyperspectral Imaging for Ore Distinction

Hyperspectral Analysis of Powder Mixtures

Paper Recycling

Rare Earth Elements

Coating thickness

Monument Preservation

Cocoa Beans