Shedding hyperspectral light on fruit quality

Characterization and classification of rotten blueberries.

Characterization and classification of rotten blueberries.

Quality inspection in the food industry traditionally has been based on direct visual inspection. This type of assessment may be subjective and significantly dependent on the expertise of the inspector. The process is in most cases labor- and time-intensive, and difficult to implement accurately on the whole product volume in a cost-effective manner. In addition, there might be quality attributes that are not visible to the human eye or that require years of training to identify reliably. While machine vision techniques are being rapidly adopted across the food industry to address these issues, they are mostly limited to RGB imaging which also limits its applicability.

Hyperspectral imaging (HSI) offers an alternative non-invasive solution to food inspection that provides objective information in real-time from large production volumes. It can be used for automated quality assessment, improving sorting accuracy and speed. In addition, the spectroscopic data from HSI can provide information about chemical content typically only available from destructive wet lab analysis (WLA).

Blueberries and other small fruits are particularly sensitive to handling and storage, and the quality parameters tend to deteriorate rapidly if the product is not managed carefully. HSI can be used for evaluating external attributes such as color, texture, firmness, surface damage, bruise, defects, and contaminants in berries and other small fruits. The HSI data can also be correlated to the WLA results to determine the internal nutritional parameters without damaging the product. Typical parameters suited for HSI analysis include taste, flavor, moisture content, dry matter, total soluble solid content, anthocyanin, acidity, pH, sugar content, and vitamin C.

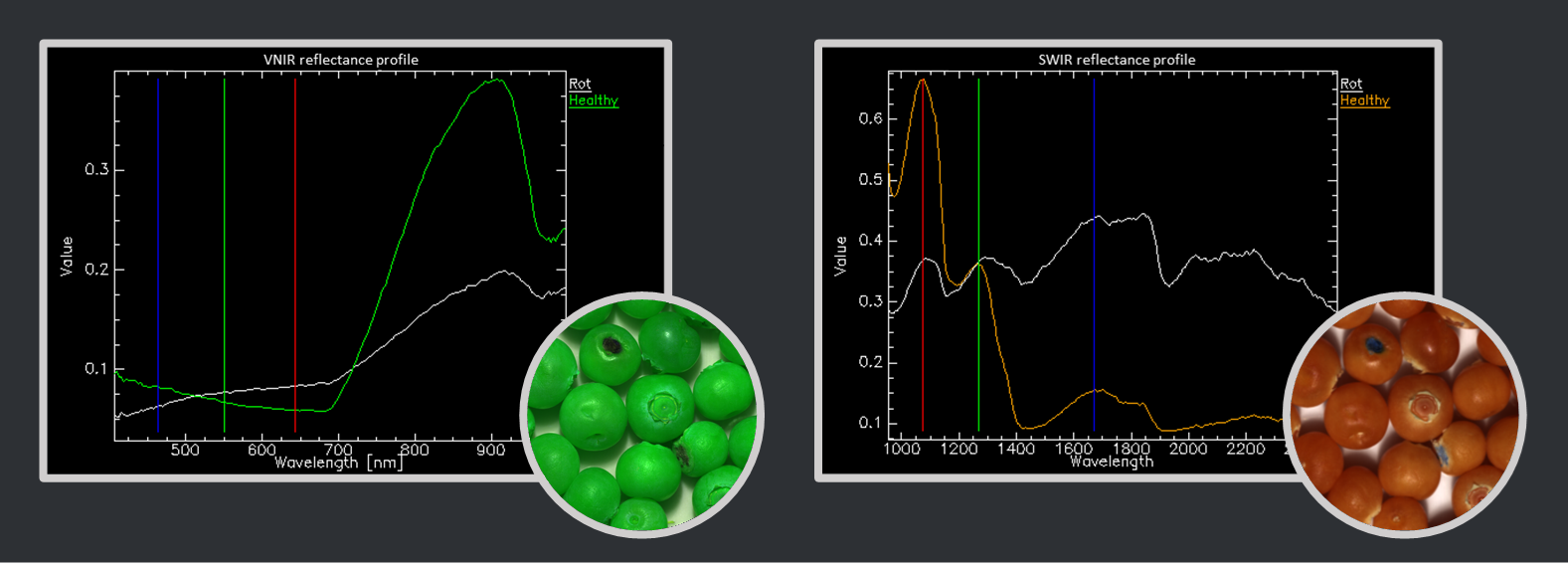

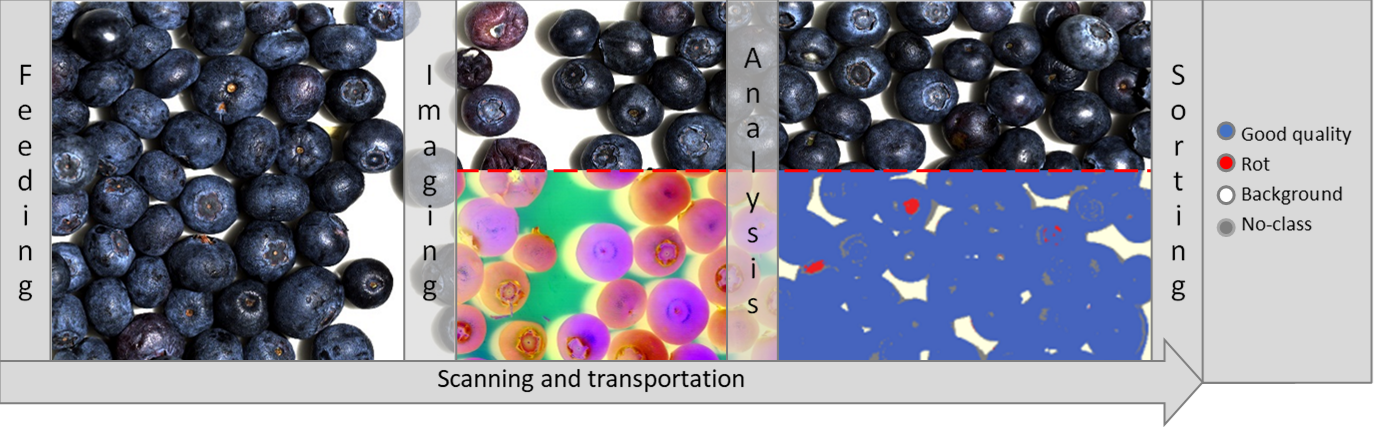

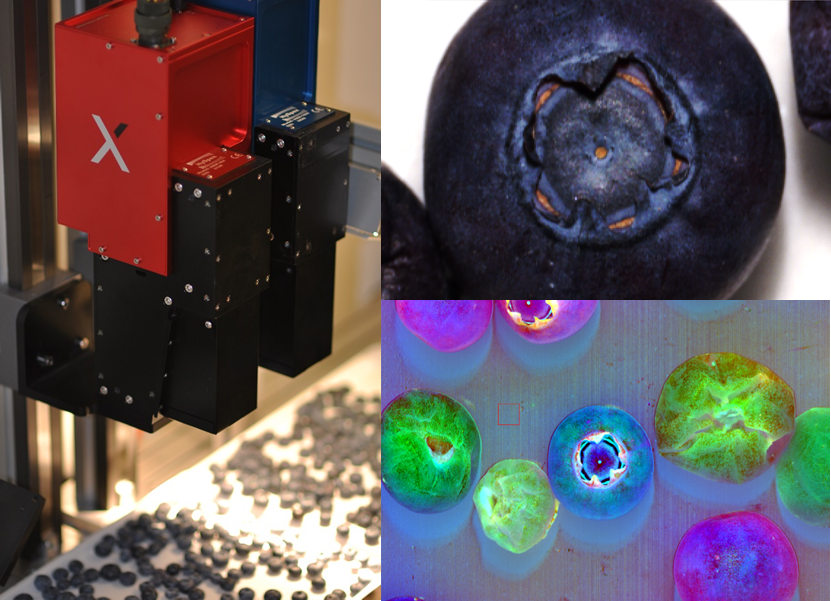

For this case study, fresh blueberries with rotten sites were scanned using HySpex Classic VNIR-1800 and SWIR-384 cameras. The full system covers the 400 – 2500 nm spectral range and operates at high speeds compatible with most conveying and sorting systems. The working distance was set to 30 cm from the berries using custom-design closeup lenses to achieve a resolution of 52 µm and 250 µm, respectively. The automated classification model (PCA) was conducted using Breeze software from Prediktera to separate healthy and rotten fruits in real-time.

Although the rotten sites on blueberries are difficult to detect at high speeds by visual inspection or in RGB mode, the rotten spots are easily identified by the hyperspectral system. The high spatial resolution of the HySpex cameras allows for precise localization and earlier detection of rottenness as compared to traditional means, even in sections as small as the calyx piece or stem residue.

Pharmaceuticals

Methane Detection

Plastic Sorting

Mineral mapping in open pit mines

Asbestos

Explosives

Hyperspectral Imaging for Ore Distinction

Hyperspectral Analysis of Powder Mixtures

Paper Recycling

Rare Earth Elements

Coating thickness

Monument Preservation

Cocoa Beans