Today the hyperspectral industrial market is flooded with cameras that have large spectral and spatial distortions and at the same time blurry optics per pixel. HySpex now offers a line of industrial cameras that are affordable but at the same time high data quality with low spatial and spectral distortions.

HySpex Baldur is utilizing the same optical design as the classic HySpex cameras. As a research tool, a camera that is as sharp spectrally as possible will be beneficial, but for an industrial system, it will be good to have a spectral resolution close to 2x the spectral sampling – i.e. a spectral resolution of 2 bands. This allows the spectral frequencies in the signal to be reproduced (Nyquist - read more here). It's also important that the spectral resolution is not much more than 2 bands to get as much information per data rate as possible, and a blurrier system will lead to a reduction in information per datarate.

HySpex Baldur is modified from HySpex classic cameras to gather 4 times as much light through the system, making it even more light-sensitive, which is especially important for the high speed and low exposure applications.

In a previous article about sharp optics the term Effective Pixel Count was defined as:

"the total spatial pixels divided by the spatial resolution in pixels, you will get the number of effective pixels. If the distortion per effective pixel is large than 10% you must reduce the effective pixel count until you have distortion at 10% of your effective pixel."

Why are low optical distortions important for industrial applications?

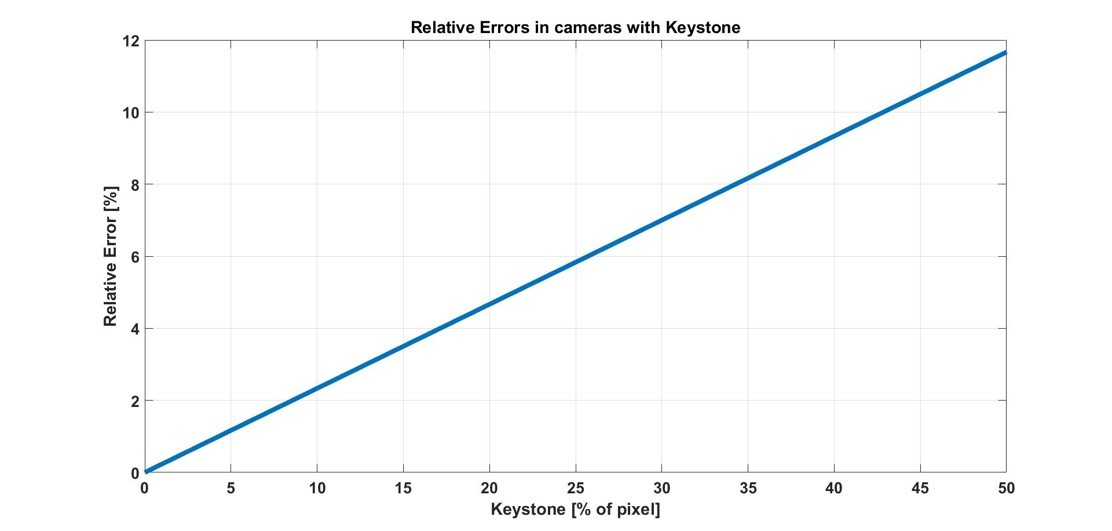

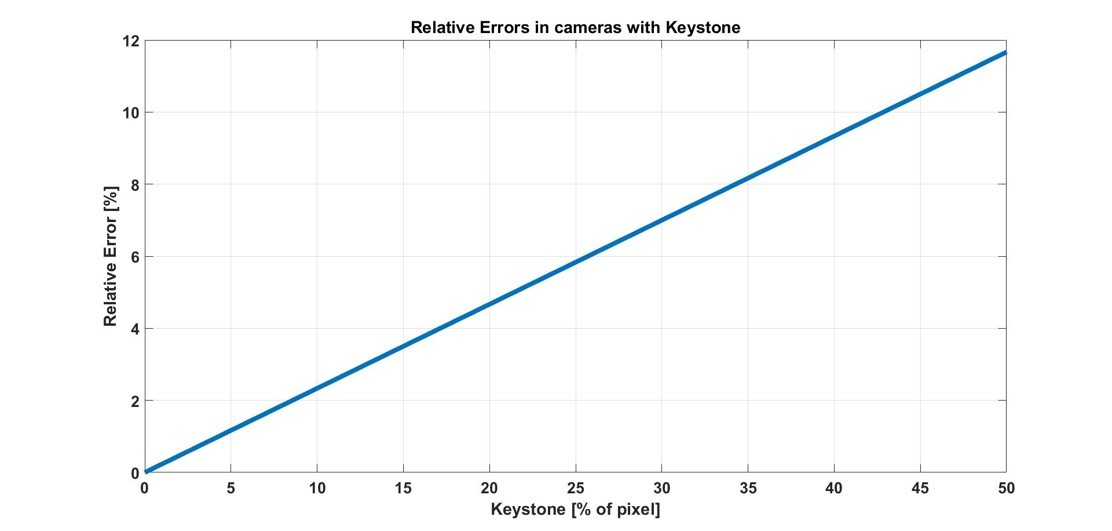

Low keystone and similar PSF for different wavelengths are of great importance in any real application (See key quality parameters). Furthermore, the relative errors in the spectrum per pixel as a function of keystone is as shown below (Ref: "Resampling in hyperspectral cameras as an alternative to correcting keystone in hardware, with focus on benefits for the optical design and data quality").

As can be seen from the graph a 42% keystone corresponds to a 10% relative error in the spectrum. This will have a huge impact on the quality of the instrument and repeatability of the system. In essence, a system with large keystone will be unstable, the spectrum will in one pixel be highly influenced by the spectrum of the object next to the pixel, resulting in a non-repeatable system.

All Baldur cameras have less than 15% keystone and smile distortions per native pixel and native band, and less than 10% keystone and smile per effective pixels and effective band.

All Baldur cameras are corrected for keystone and smile in the optics, and no additional processing step (Resampling) is introduced.

What makes HySpex Baldur line of cameras so good?

Flexibility

All HySpex Baldur cameras support multiple regions of interest (MOI). HySpex Baldur V-1024N supports up to 8 independent regions and gives a speed increase relative to the reduction of spectral bands from the native resolution. HySpex Baldur S-384N and S-640i-N both support independent band selection from one band to the full range without being connected bands - also resulting in a speed increase directly proportional to the reduction of bands relative to the native number of bands.

All HySpex Baldur cameras have various FOV options for different working distances.

Triggering

All cameras can be triggered internally, and all cameras support several kinds of external triggering (TTL at different levels and LVDS). All cameras are operating in “Integrate While Read mode" making it possible to use almost the whole frame period for exposing the detector, this is very important when running the system at high acquisition speeds.

Speed

HySpex Baldur industrial cameras deliver the most information per data rate of all hyperspectral cameras available today. The speed is scalable with reducing the number of spectral channels readout.

Reliability

All cameras are still delivered with a traceable calibration to NIST and PTB standard. They have a spectral resolution of two bands making it spectrally reliable when using multiple cameras with the same model/algorithm.

All Industrial camera within the same wavelength range have the same center wavelengths.

The design is originally made for airborne use and has been flying since 2003, the design is extremely robust and can withstand vibrations and harsh environments. HySpex has been delivering hyperspectral cameras since 2003 and no products have reached the end of life.

All HySpex Baldur cameras have less than 15% keystone and smile distortions per native pixel and native band, and less than 10% keystone and smile per effective pixels and effective band.

Light sensitivity

The light sensitivity of HySpex Baldur is about 4 times higher than HySpex classic systems making it perfect for high-speed applications.

SDK

All HySpex cameras; Baldur, Classic and Mjolnir, are delivered with a high-end SDK and library that makes it simple to integrate the HySpex HW into any third-party software and hardware solution.

Third-Party processing software

HySpex is compatible with all third-party processing software suppliers on the market today. HySpex has started a closer collaboration with Prediktera by investing in Prediktera. Since early 2018, HySpex has collaborated closely with Prediktera, , developing the best HW and SW solution on the market. Today, seamless HW and SW integration is offered with all cameras and accessories:

- Turnkey HW and SW solution for the customer to test and develop their own models/applications easily and fast.

- Both high-end line of hyperspectral cameras for R&D and an industrial line, together with a tool to downgrade high-end data to comparable industrial line data as well as a tool to suggest the wavelength range with the best detection potential for a given application.

- Fast cameras that can run at max speed while running the models real-time on a runtime engine that supports both CPU and GPU computing.

- Easy export of models from offline SW package to the runtime engine.

- “Connector Software” to interface with the customer's graders, sorters or similar. This SW solution takes care of the timing of the mid-exposure of each frame (or position and time of objects) and when a decision must be made from the results. The SW has been interfaced with several different machine suppliers’ SW to control PLCs for sorting applications.

Ending remarks

All camera models by NEO not containing an "N" in the name are extremely sharp per pixel and per band, and have very low distortion per pixel, thus making it a perfect research tool.

The Baldur line of cameras is designed to have a spectral resolution at almost exactly 2 bands making it spectrally more repeatable to avoid spectral aliasing while maintaining most of the sharpness spatially. HySpex Baldur instruments, having all of the above-mentioned qualities, makes them perfect for industrial applications.

When selecting a hyperspectral camera for a specific application, the minimal object that is to be detected should be defined, and allow at least two effective pixels per object (in one direction). Then, the size of e.g. the conveyor belt will define how many effective pixels, and thus, native pixels for that systems, is needed for that specific application.

It is the effective pixel count for an imaging system that is the key quality parameter affecting the price. Therefore the price/effective pixel ratio is a good measure of pricing for any imaging spectrometer. HySpex Baldur has the lowest price per effective pixel on the market today.

HySpex Baldur V-1024 N installed in the Fish Quality Analyzer, developed in an FHF funded research project, KVASS. The participating partners besides HySpex are Maritech, NOFIMA, Lillebakk, Lerøy, Havfisk, and Prediktera. The Fish Quality Analyzer is offered as a commercial product by Maritech, Norway.

HySpex Baldur V-1024 N installed in the Fish Quality Analyzer, developed in an FHF funded research project, KVASS. The participating partners besides HySpex are Maritech, NOFIMA, Lillebakk, Lerøy, Havfisk, and Prediktera. The Fish Quality Analyzer is offered as a commercial product by Maritech, Norway.

HySpex Baldur V-1024 N installed in the Fish Quality Analyzer, developed in an FHF funded research project, KVASS. The participating partners besides HySpex are Maritech, NOFIMA, Lillebakk, Lerøy, Havfisk, and Prediktera. The Fish Quality Analyzer is offered as a commercial product by Maritech, Norway.

HySpex Baldur V-1024 N installed in the Fish Quality Analyzer, developed in an FHF funded research project, KVASS. The participating partners besides HySpex are Maritech, NOFIMA, Lillebakk, Lerøy, Havfisk, and Prediktera. The Fish Quality Analyzer is offered as a commercial product by Maritech, Norway.